A microfluidic solution for impossible proteins

From scouting to scaling with VIB Tech Watch, the Masschelein and Saelens labs, and the VIB Protein Core

Nanoliter droplets navigate across a microchip, automatically testing hundreds of protein expression conditions that would take researchers months to attempt manually. This digital microfluidics breakthrough tackles biology's persistent challenge of producing difficult proteins. VIB's systematic adoption of this innovation—from scouting to validation to scaling—demonstrates how breakthrough technologies reach the bench when scientists need them most.

Sydney Brenner, Nobel Prize-winning geneticist, once observed that "progress in science depends on new techniques, new discoveries, and new ideas, probably in that order." Note the primacy of new techniques, reflecting how they serve as the great enablers of scientific advancement.

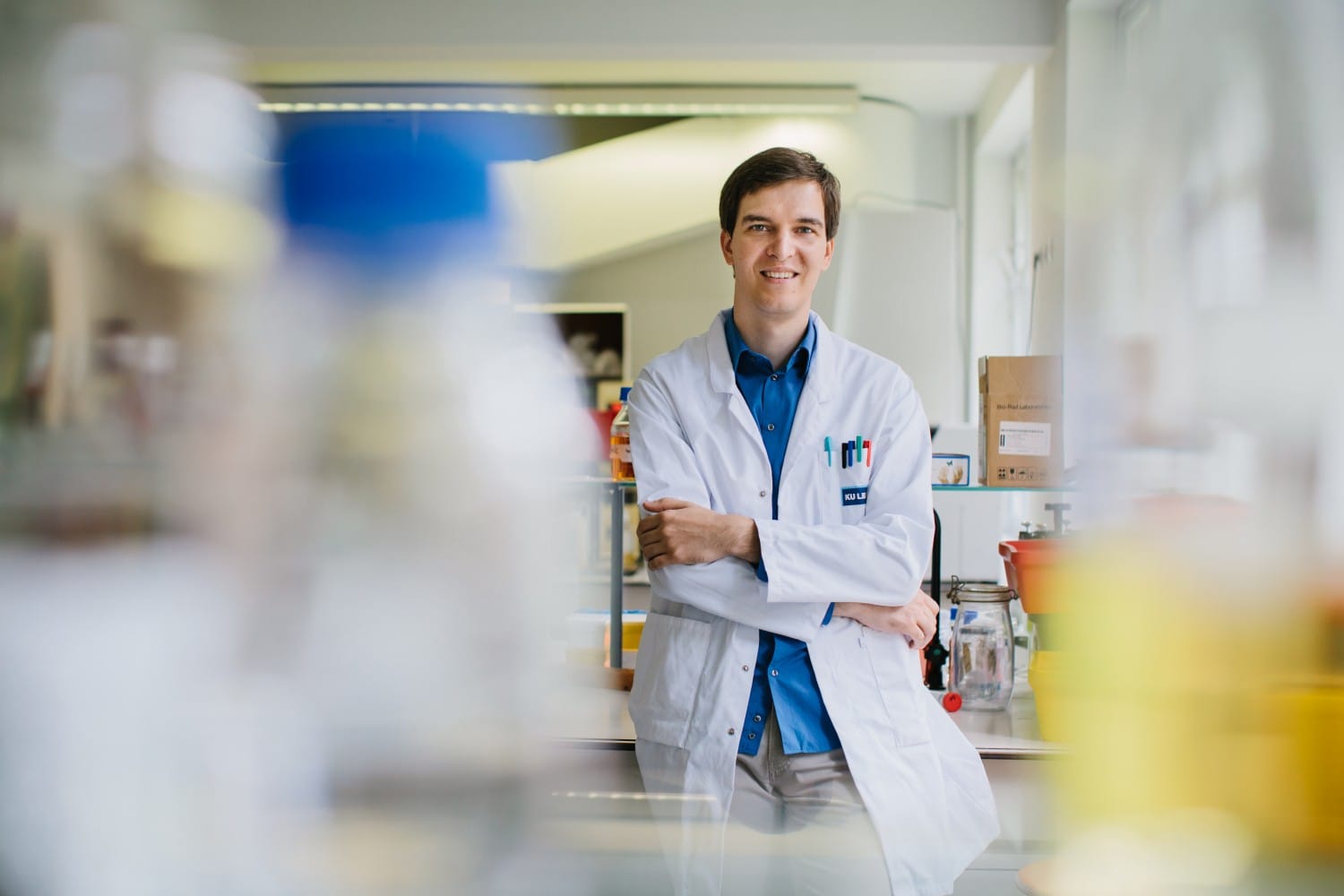

Consider Joleen Masschelein's predicament in early 2022. Her lab at the VIB-KU Leuven Center for Microbiology was studying antibiotic resistance, trying to understand how Serratia bacteria evade the broad-spectrum antibiotic zeamine. The culprit was a gene encoding GNAT, a resistance enzyme that needed to be produced and purified for study. Simple enough, except that GNAT kept killing their E. coli cells.

For six months, the team tried everything: different strains, expression hosts, affinity tags, purification conditions. Nothing worked. The enzyme was simply too toxic for traditional bacterial systems. This is the kind of technical bottleneck that can stall research for years, but Masschelein's story has a different ending, one that reveals how VIB has built robust systems to ensure scientists have access to breakthrough technologies precisely when they need them.

Step 1: Scout

While Masschelein's team was wrestling with their uncooperative enzyme, VIB Tech Watch was at work, doing what they do best: scanning the horizon for emerging technologies. As early as 2019, they had spotted patents from a UK startup called Nuclera, initially focused on DNA synthesis using electro-wetting technology. In 2022, when industry contacts introduced them to CEO Michael Chen, they discovered the company had made a pivotal shift, combining their electro-wetting technology with cell-free protein synthesis.

"Cell-free protein synthesis was already on our radar," explains Toon Swings from VIB Tech Watch. "We had multiple VIB groups struggling with difficult protein expression, and previous projects in this space hadn't quite materialized. When we looked at what Nuclera's technology could do, it looked like a very good opportunity to fill that gap."

Toon Swings ©VIB-Ine Dehandschutter | Nuclera eProtein Discovery system

Cell-free expression systems have existed for decades, but they've been hampered by significant limitations, typically offering what Toon calls "a one-shot deal" with minimal customization. Either your protein gets expressed in the system or it doesn't.

Nuclera's innovation was different: digital microfluidics that could test up to 192 different combinations of constructs and conditions simultaneously using nanoliter-scale droplets.

"The droplets move and dance on the cartridge," Toon says, with genuine excitement in his voice. "I've watched it about 40 times now, and it's always mesmerizing. But it's also brilliant technology for miniaturization and automation."

Nuclera invited VIB to an “alpha program” with limited worldwide slots and a tight deadline. Tech Watch moved fast, contacting VIB researchers who'd previously tried cell-free synthesis. They received enthusiastic responses from both Joleen Masschelein's team and Xavier Saelens' lab at VIB-UGent Center for Medical Biotechnology, and secured one of just five global prototype slots within weeks. In short order, the device arrived at Tech Watch's demo lab in Leuven.

What is cell-free protein synthesis?

Traditional protein production uses living cells (like E. coli) as factories. Cell-free systems aim to skip the living cell entirely, using just the cellular machinery (ribosomes, enzymes, and energy molecules) in a test tube. This eliminates many problems like cell toxicity, but historically offered limited customization options.

What does Nuclera's eProtein Discovery system do?

Nuclera combines cell-free synthesis with digital microfluidics, a technology that manipulates tiny droplets on a chip using electrical fields. Each nanoliter droplet becomes a miniature experiment, testing different DNA constructs and expression conditions simultaneously.

Key advantages

Construct optimization: Test multiple solubility tags (His, GST, MBP), truncations, polymorphisms, and isoforms on the same cartridge.

Rapid iteration: Go from DNA to protein expression data in hours versus weeks for traditional workflows.

Scaling bridge: Results provide actionable data for optimizing traditional bacterial expression systems for further scaling.

Step 2: Validate

When Hans Gerstmans, a postdoc in Joleen Masschelein’s lab, brought their problem protein to the Nuclera's eProtein Discovery system, they discovered the platform's true power. The system's ability to screen 24 different DNA constructs against 8 customizable expression conditions meant they could test many different approaches simultaneously—something that would have taken months to do manually.

The system quickly identified the winning combination: an N-terminal thioredoxin tag combined with Acetyl-CoA yielded optimal GNAT expression. Armed with these conditions, the scientists could finally produce the protein that had eluded them for six months.

"This was the first time this specific GNAT enzyme was successfully expressed," Masschelein noted. “Using the optimized conditions, we produced sufficient quantities for functional assays, confirming that Acetyl-CoA was necessary for GNAT's activity and enabling mass spectrometry and detailed mechanistic studies.”

Joleen Masschelein (standing) ©VIB-Fred Loosen | Hans Gerstmans ©Kevin Faingnaert

Tech Watch's next move was crucial: they launched an adoption call across all VIB centers, offering testing kits to any interested researcher. Soon after, eight out of the ten centers were actively testing the technology, indicating that protein expression problems were common.

"From a Tech Watch point of view, that's what we're always looking for," Toon explains. "Many new technologies come out every year, but the crucial aspect of making a technology successful is finding a key application and a group in VIB where the technology is truly necessary to proceed. If it starts with one group, it can spread to many groups due to information sharing within VIB. Joleen's group was a very good pioneer since they had an application perfectly suited for the technology."

Step 3: Scale

By early 2024, the results were too compelling to keep in the demo phase. But Tech Watch faces a fundamental challenge: they're designed to de-risk technologies, not run services. This gap between promising prototype and routine availability is where many technologies falter. But the VIB Technologies program is designed to bridge this gap.

The VIB Technologies’ Protein Core had been tracking Nuclera's progress from the beginning, recognizing that this technology aligned perfectly with their core mission of empowering scientists with cutting-edge tools backed by expert guidance.

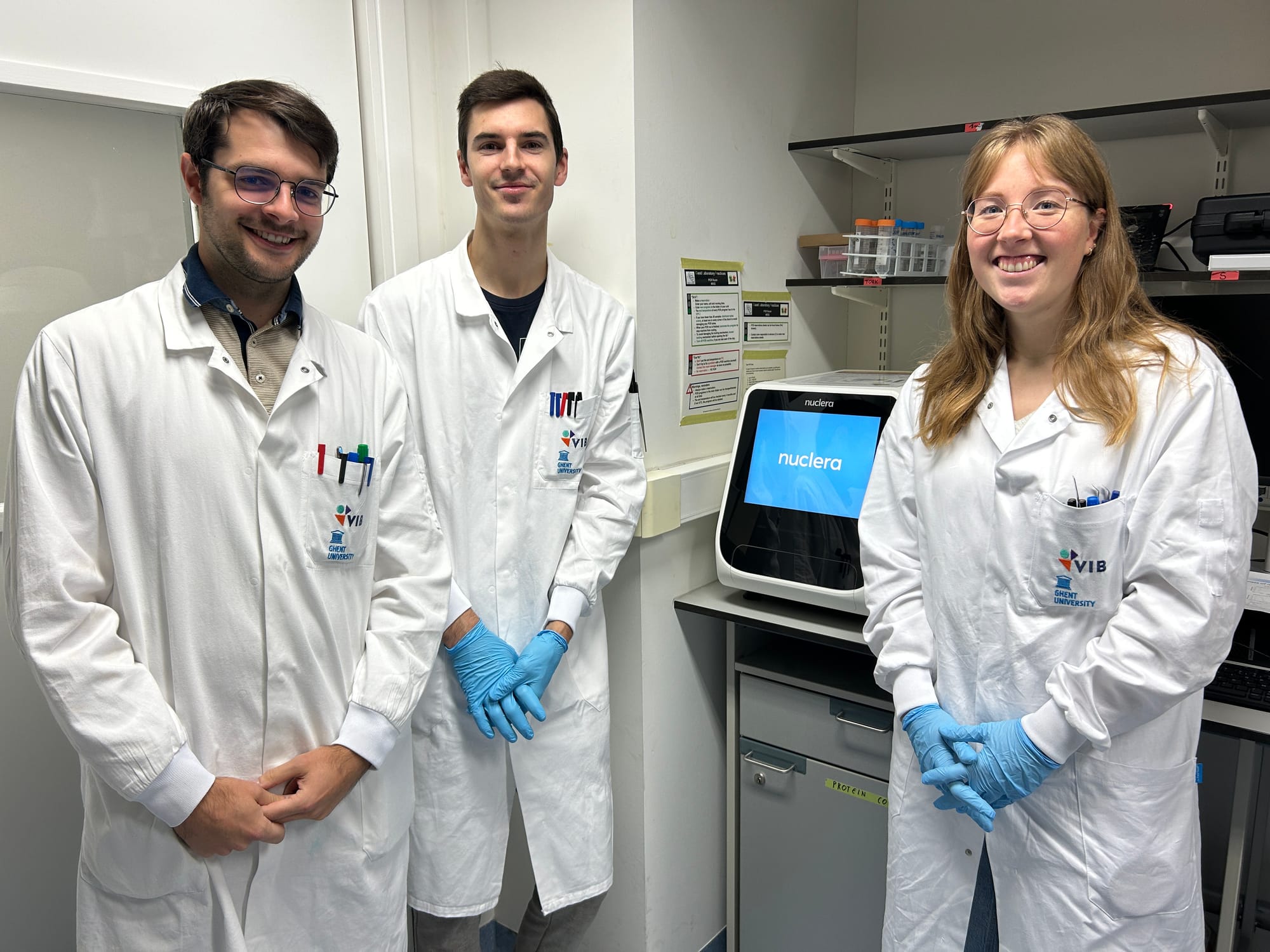

"What set Nuclera apart was their effort to bridge the gap between cell-free screening and in vivo expression,” explains Jelmer Porrez, Lab Technician at the Protein Core and one of the people responsible for operating the platform. “Their platform not only identifies optimal constructs and tags but also provides actionable recommendations for E. coli expression, including strain selection and additive use based on screening results."

“This comprehensive approach, combined with an outstanding technical support team that is always available for experimental design tips and interpreting results, has meant that we can offer faster turnaround times, reduce reagent use, and explore far more conditions in less time than we could before,” adds Sarah Van der Stiggel, also a Core facility technician who was also trained on the instrument.

For the Protein Core, it was clear that the Nuclera technology would enhance their existing workflows by filling a specific niche for rapid prototyping of challenging targets like toxic proteins and membrane proteins, and prove invaluable for early-stage feasibility studies where rapid iteration was key.

"Think strategically upfront and let the data guide your decisions," advises Kevin Balcaen, Senior Protein Expert at the VIB Protein Core. "Take full advantage of the platform's multiplexing capabilities by investing time in thoughtful experimental design—test multiple tags and additives rather than playing it safe. Use the rapid turnaround to iterate quickly when initial results suggest refinements, and trust the system's predictive data to guide your scaling strategy from cell-free screening to bacterial expression."

Continuous innovation: Lowering barriers further

Tech Watch's role didn't end at successful deployment. They maintain close contact with Nuclera, tracking developments like the recent membrane protein capability and upcoming antibody production features expected in 2026. But they're also systematically addressing remaining friction points.

For example, the DNA preparation step currently requires PCR work, which has proven a stumbling block for some groups. Tech Watch is now collaborating with DNA synthesis companies to provide full-length DNA fragments ready for immediate loading, eliminating the PCR step entirely.

This continuous refinement exemplifies Tech Watch's broader approach: their intimate knowledge of both the technology and user needs allows them to not only provide access to cutting-edge tools, systematically lower barriers to adoption and also help improve the technology.

The innovation engine at work

Today, three Nuclera devices operate across VIB: one at the Protein Core for routine services, one at Masschelein's lab for ongoing research, and one at the VIB-KU Leuven Center for Brain & Disease Research in Leuven. Masschelein's lab is now deep into GNAT mechanism studies, exploring strategies to combat antibiotic resistance. Across VIB, previously impossible proteins are entering routine production, each one enabling multiple downstream studies.

The Nuclera story illustrates VIB's systematic innovation engine: a three-stage process that scouts emerging capabilities, validates real-world utility, and scales successful technologies into routine services. The feedback loop is crucial: user experiences inform the next round of technology searches, creating an adaptive system that anticipates rather than reacts to research needs.

This returns us to Brenner's insight about scientific progress. New techniques enable new discoveries, which generate new ideas. VIB's pipeline accelerates this entire cycle, ensuring that breakthrough research isn't limited by access to breakthrough tools, but only by the creativity to use them well.

For VIB researchers, the message is clear: that impossible protein you gave up on might be worth a second look.

Reach out to our VIB Technologies experts: